MINGNO is a manufacturer specializing in custom CNC milling parts processing. The company is committed to providing customers with high-precision, high-quality CNC milling services to meet the needs of different industries such as electronic equipment housings, connectors, and electronic devices. Through advanced processing equipment and exquisite craftsmanship, MINGNO is able to provide customers with high-quality parts solutions, which are widely used in many fields such as automobiles, aviation, medical, and electronics.

What is CNC Milling?

CNC Milling (Computer Numerical Control Milling) is a precision manufacturing process that processes materials by controlling the movement of milling cutters through a computer numerical control system. CNC milling uses a rotating milling cutter on a workbench to cut, mill, drill or engrave metal or plastic parts. Compared with traditional manual processing methods, CNC milling can achieve high-precision, mass production, and can handle complex geometries and complex dimensional requirements.

CNC Milling Process

The process of CNC milling is very flexible, and different processes can be selected according to different processing requirements. Common processes include:

Slotting: used to cut slots in parts, suitable for matching parts of mechanical parts.

Drilling: Processing holes of different sizes on parts, often used in mechanical connection parts.

Face Milling: Through the cutting of the milling cutter, the excess part of the workpiece surface is removed to obtain a flat surface.

Contour Milling: used to process the edge or contour of the part to ensure the outer dimensions of the part.

Thread Milling: Processing internal and external threads on workpieces, commonly used in the production of connectors.

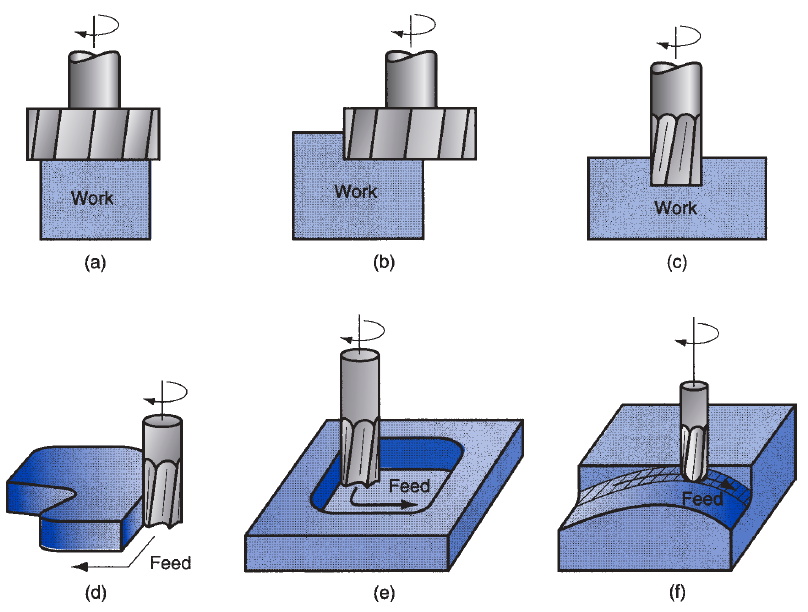

Face milling: (a) conventional facemilling,(b)partialface milling,(c)end milling, (d) profile milling,(e) pocket milling, and (f) surfacecontouring.

Material Selection

MINGNO provides a variety of common metal and non-metal materials for CNC milling. Commonly used materials include:

Aluminum Alloys

Features: light weight, high strength, corrosion resistance, easy processing.

Applications: aerospace, automotive industry, electronic equipment housing, etc.

Stainless Steel

Features: corrosion resistance, high temperature resistance, high strength.

Applications: medical equipment, chemical equipment, food processing, etc.

Titanium Alloys

Features: extremely high strength and corrosion resistance, and light weight.

Applications: high-precision fields such as aviation and medical implants.

Plastics

Features: light weight, easy processing, suitable for complex parts manufacturing.

Applications: electronic products, medical equipment, consumer products, etc.

Copper Alloys

Features: good electrical and thermal conductivity, easy to cut.

Applications: electrical components, connectors, electronic devices, etc.

MINGNO's CNC milling service can provide micron-level high-precision processing. According to customer needs, the following accuracy requirements can be achieved:

Dimensional accuracy: ±0.01mm

Surface roughness: Ra ≤ 0.8µm

Geometric accuracy: suitable for processing complex shapes and fine features.

Surface treatment

After CNC milling parts are processed, surface treatment is usually required to improve the durability and appearance of the parts. Common surface treatment methods include:

Anodizing: Increase the hardness and corrosion resistance of the aluminum surface, often used for aluminum alloy parts.

Sandblasting: Provide a uniform smooth effect on the surface of the part and remove oxides.

Electroplating: Increase the corrosion resistance and aesthetics of the part surface, often used for steel parts.

Coating: Increase the wear resistance and corrosion resistance of the parts, such as polyurethane coating, PTFE coating, etc.

CNC milling parts have a wide range of applications, and optimizing their application performance can be achieved through reasonable design and material selection:

Precise design: Make reasonable design according to the functional requirements of the parts, optimize the cutting path, and reduce the errors generated during the processing.

Material selection: Select the appropriate material according to the application scenario to ensure the reliability of the parts in high temperature, pressure or corrosive environment.

Surface treatment optimization: Select the most appropriate surface treatment method according to the functional requirements of the parts to improve the durability and aesthetics of the parts.

Maintenance and care

CNC milling services require regular maintenance and care to ensure the normal operation of the equipment and extend its service life:

Clean the equipment regularly: Regularly remove the cutting residues on the machine to keep the machine clean.

Check the lubrication system: Ensure that the mechanical parts and moving parts are well lubricated to avoid wear.

Replace the tool regularly: Regularly check and replace the worn tool to maintain the processing accuracy.

Maintain the cooling system: Ensure the normal flow of coolant to prevent overheating and tool damage.

FAQ

What is the difference between CNC milling and traditional milling?

CNC milling relies on computer program control, which can provide higher precision, efficiency, and can process complex shapes, while traditional milling requires manual operation, low precision and low efficiency.

How to choose the right material for CNC milling?

The material selection should be based on the application scenario of the part (such as temperature, corrosion, load, etc.). Common material choices include aluminum alloy, stainless steel and titanium alloy, etc.

How to control the accuracy of CNC milling?

CNC milling accuracy is mainly guaranteed by program design, machine calibration, tool selection and cutting parameter control. Regular inspection and maintenance of equipment are the key to ensuring accuracy.

What effect does surface treatment have on CNC milling parts?

Surface treatment can improve the durability, corrosion resistance and aesthetics of parts, and ensure that parts can work properly in harsh environments.

How to reduce errors in CNC milling?

Errors can be effectively reduced by optimizing tool paths, regularly maintaining equipment, and using high-precision materials and tools.