What is 5 Axis CNC Machining?

5 Axis CNC Machining is a high-end precision machining technology that can simultaneously control the movement of five axes during machining. This technology allows for one-time efficient machining of workpieces with complex geometries, especially for parts with complex curved surfaces and multi-angle features. Compared with traditional three-axis machining, five-axis machining can avoid multiple clampings and improve machining efficiency and precision. MINGNON has a professional Evermi five-axis five-link 850 machine, which performs particularly well in machining complex parts. Its high speed and high precision make it an ideal choice for precision manufacturing.

Features of 5 Axis CNC Machining

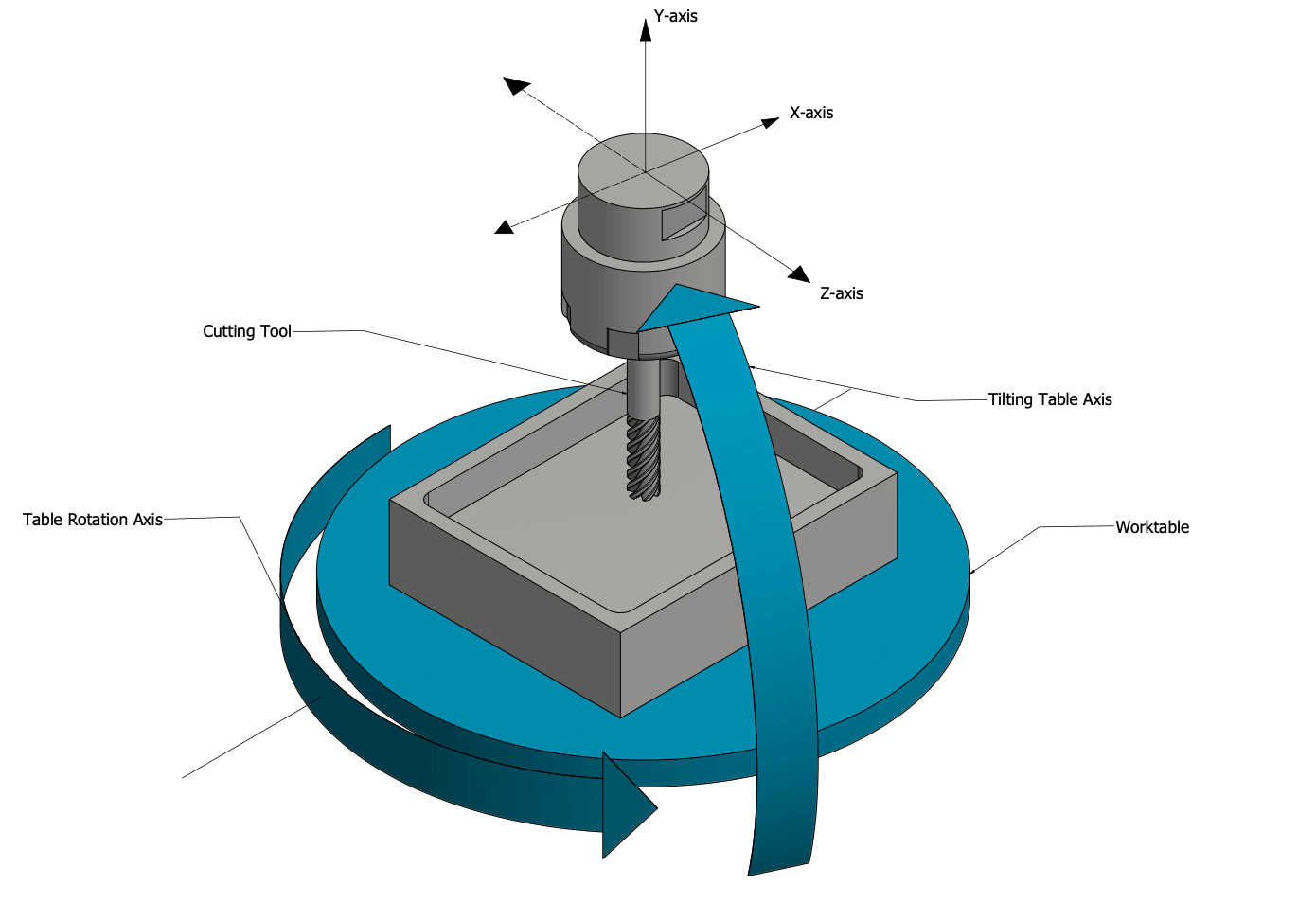

The core advantages of five-axis machining are flexibility and high precision. Its unique five motion axes (X, Y, Z axes plus rotating A and C axes) enable the equipment to process workpieces at any angle without frequent adjustments to the fixture position, thereby reducing errors. In addition, five-axis machining supports a variety of materials, including aluminum, titanium, stainless steel and high-performance plastics, which are suitable for multi-field needs. The highlight of the Evermi five-axis five-link 850 machine is its excellent motion control capability, which can achieve a machining accuracy of ±0.001mm, while having high-speed machining capabilities, significantly shortening the machining cycle.

Functions and Applications

The main function of five-axis machining is to achieve precise manufacturing of complex geometric shapes, especially in the fields of aerospace, automobiles, medical, mold manufacturing and high-end consumer products. For example, in the aerospace industry, it can be used to process high-precision parts such as turbine blades and wings; in the automotive field, it can produce complex structural parts such as engine parts and molds; in the medical field, it is used to manufacture orthopedic implants and surgical tools; in the mold manufacturing field, five-axis machining is used to achieve efficient manufacturing of complex curved surface molds. In addition, five-axis machining is also widely used in the field of jewelry and luxury goods, providing excellent process support for high-end products.

How to maintain and maintain

In order to ensure the performance and life of five-axis CNC equipment, regular maintenance is essential. The machine tool should be kept clean, especially the chip cleaning after processing to prevent affecting the running accuracy. Regularly check the lubrication system of the equipment to ensure that the bearings and guides are fully lubricated, and monitor the status of the coolant to avoid excessive use and reduce the cooling effect. In addition, the motion axis of the machine tool needs to be calibrated regularly to maintain the processing accuracy. For the Evermi five-axis five-link 850 machine, it is recommended to perform a comprehensive overhaul every 1000 hours and perform regular maintenance according to the equipment manual.

FAQ

What are the material requirements for five-axis machining?

Five-axis machining is suitable for a variety of materials, but it is necessary to ensure that the material meets the hardness and strength range of the machining equipment, such as aluminum, titanium, stainless steel and high-performance plastics.

Is a special fixture required?

In most cases, five-axis machining does not require frequent fixture changes, but for workpieces with special shapes, custom fixtures may be required to ensure stability.

How to ensure machining accuracy?

The equipment should be calibrated before use, and the quality of the cutting tool should be ensured. At the same time, the various parameters of the equipment should be checked regularly to avoid loss of accuracy due to wear.

Is five-axis machining suitable for small-batch production?

Suitable. Five-axis machining can quickly set up and process a variety of complex parts, especially suitable for small-batch customization needs.

What are the highlights of the Evermi five-axis five-link 850?

The machine has high dynamic response and precise motion control, can support a variety of complex machining tasks, and is suitable for efficient and high-precision industrial production.

Is the cost of five-axis machining high?

Due to its high efficiency and reduced clamping times, five-axis machining saves time and cost relatively. Although the initial equipment investment is high, it is cost-effective in the long run.

How to choose a tool?

Choose the right tool according to the hardness of the material, the processing speed and the required precision. For example, carbide tools are suitable for metal processing.

Is it easy to collide during processing?

Five-axis processing requires precise program settings. It is recommended to use professional CAM software for path optimization to reduce the risk of collision.

Does it support the processing of complex surfaces?

Yes. Five-axis processing is particularly good at processing complex surfaces and multi-angle features, and can complete the manufacturing of finished products in one go.

Does the five-axis equipment have high requirements for operators?

Operators are required to have certain programming and equipment operation skills, but modern five-axis equipment usually has a friendly operating interface, which reduces the threshold for use.

MINGNON is committed to providing professional CNC processing services, combined with the excellent performance of Evermi's five-axis five-link 850 machine, which can meet the diverse high-end needs of customers. If you need to know more, please feel free to contact us!